EQUIPMENT & FACILITY

Our 80,000 square feet of manufacturing space in Union, NJ is fully equipped to meet your needs.

Production

| Automatic Screw Machines | |

| Qty | Machine |

| 1 | Acme-Gridley, 8-spindle, 1-5/8″ capacity |

| 1 | Acme-Gridley, 8-spindle, 2″ capacity |

| 4 | Acme-Gridley, 8-spindle, 2-5/8″ capacity |

| 2 | New Britain, 6-spindle, 1″ capacity |

| 3 | Acme-Gridley, 6-spindle, 1-1/4″ capacity |

| 7 | New Britain, 6-spindle, 1-5/8″ capacity |

| 4 | New Britain, 6-spindle, 2-1/4″ capacity |

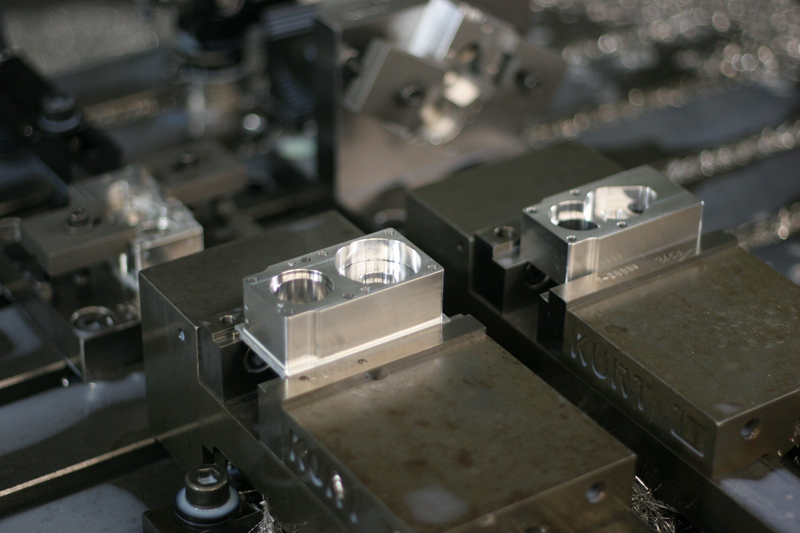

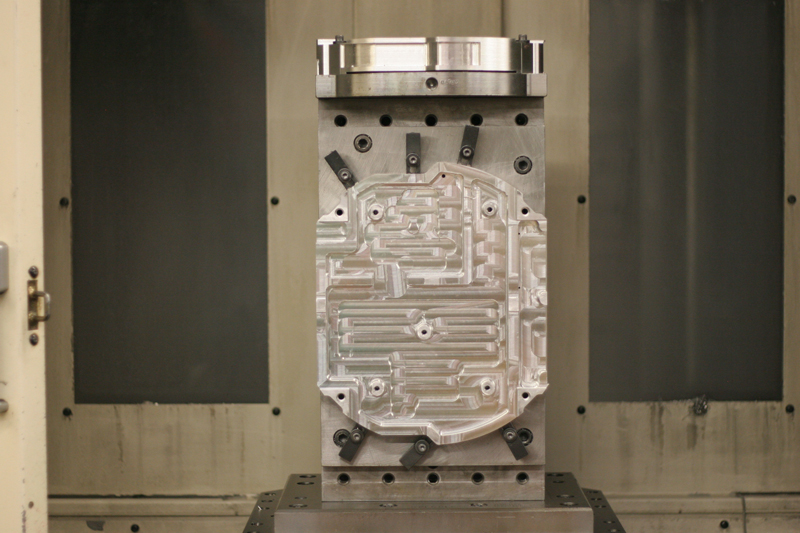

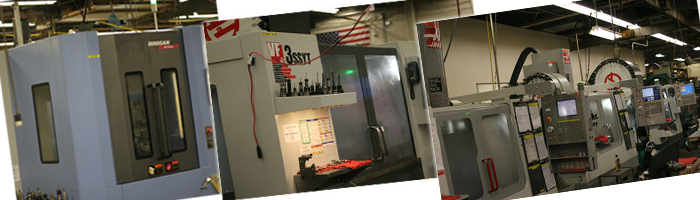

| CNC Machine Centers – Vertical | ||

| 1 | Matsuura MC800V-DC V.M.C. Twin Spindle with Pallets 3 axis (30×2 Tools) | |

| 1 | Matsuura MC800V-DC V.M.C. Twin Spindle 3 axis (30×2 Tools) | |

| 1 | Matsuura MC-560V V.M.C. 4 axis (25 Tools) | |

| 1 | Matsuura MC-760V-DC V.M.C. Twin Spindle 4 axis (25×2 Tools) | |

| 1 | Matsuura MC-1000VS V.M.C. 4 axis (25 Tools) | |

| 1 | Matsuura MC-1000VS 3 axis (25 Tools) | |

| 1 | Matsuura MC-500V-DC V.M.C. Twin Spindle 3 axis (25×2 Tools) | |

| 1 | Matsuura MC-500V V.M.C. Twin Spindle 4 axis (20×2 Tools) | |

| 2 | Mazak V-7.5 V.M.C.’s 3 axis (30 Tools) | |

| 1 | Matsuura MC-510VC V.M.C. 4 axis (30 Tools) | |

| 1 | Matsuura MC-1500V V.M.C. 3 axis (40 Tools) | |

| 1 | Mitsui Seiki 4DN II V.M.C. Jig Bore 3 axis (16 Tools) | |

| 4 | Bostomatic 312 V.M.C.’s 4 axis (12 Tools) | |

| 2 | Bostomatic 312 V.M.C.’s 3 axis (12 Tools) | |

| 2 | Fanuc Robo Drill X-T14iB V.M.C. with Pallets (14 Tools) 15,000 RPM’s | |

| 1 | Fanuc Robo Drill X-T14iB V.M.C. (14 Tools) 15,000 RPM’s | |

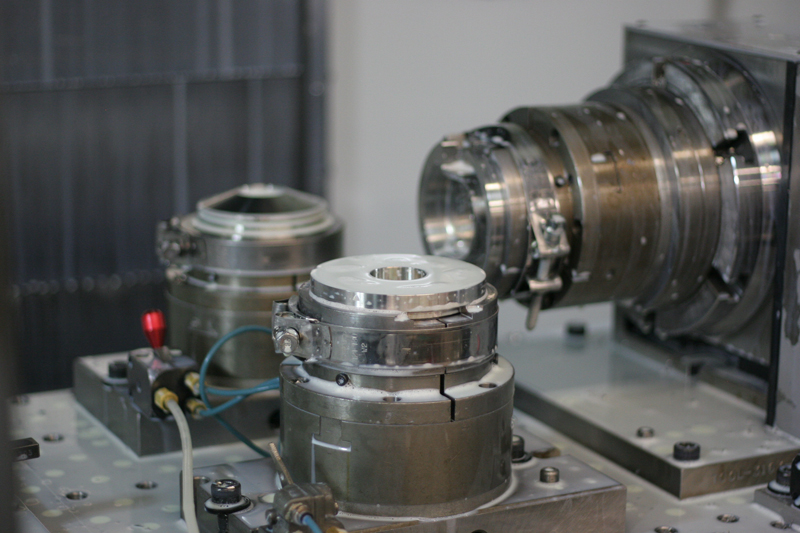

| CNC Machine Centers – Horizontal | ||

| 2 | Leblond Makino A55 Horz. 3 axis (60 Tools) 15,000 RPM’s | |

| 2 | Leblond Makino A55 Horz. 4 axis (60 Tools) 15,000 RPM’s | |

| 1 | Leblond Makino A66 Horz. 4 axis (60 Tools) 15,000 RPM’s | |

| 1 | Leblond Makino A77 Horz. 4 axis (90 Tools) 12,000 RPM’s | |

| 1 | Toyoda FA450 II Horz. 3 axis (60 Tools) 12,000 RPM’s | |

| 2 | Matsuura MC-600W-45 Horz. 4 axis (60 Tools) 6,000 RPM’s | |

| 2 | Matsuura MAM-600WF-PC-Z Horz. 4 axis (60 Tools) 12,000 RPM’s | |

| 1 | Kitamura MicroCenter Hx300 Horz. (40 Tools) 15,000 RPM’s | |

| 1 | Mazak MicroCenter H-12 Horz. (60 Tools) 4,000 RPM’s | |

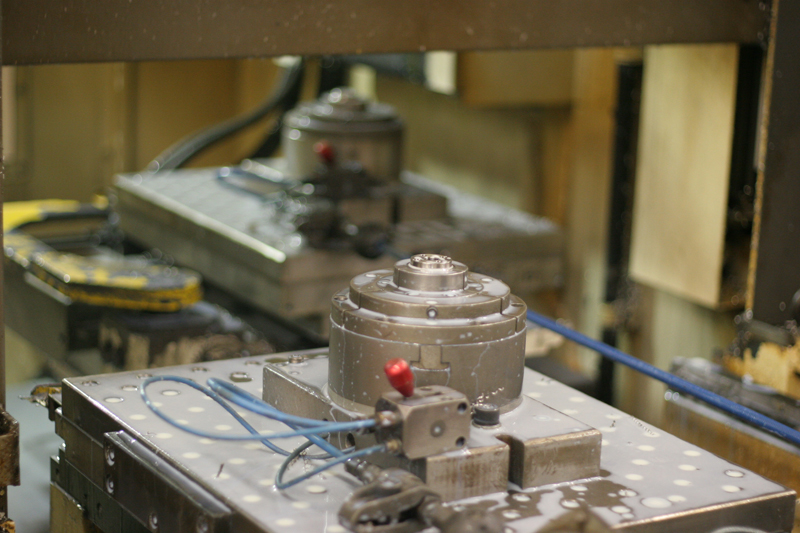

| CNC Turning Centers | ||

| 7 | Wasino J5’s with Robotic Load/Unload 8″ Chuck (12 Tools) | |

| 1 | Wasino J5n with Robotic Load/Unload 6″ Chuck (8 Tools) | |

| 5 | Wasino J1’s with Robotic Load/Unload 5″ Chuck (8 Tools) | |

| 3 | Wasino J6’s with Robotic Load/Unload 4″ Chuck (Gang Tools) | |

| 3 | Wasino J6’s with LNS Barfeed (Gang Tools) 2″ Bar Capacity | |

| 1 | Mazak Multiplex 420 Mark II Twin Spindle/Twin Turret 8″ Chuck (12 Tools) | |

| 1 | Mazak Multiplex 410 Twin Spindle/Twin Turret 6″ Chuck (12 Tools) | |

| 3 | Hardinge Cobra 42’s 6″ Chuck (12 Tools) | |

| 6 | Hardinge CHNC’s 4″ Chuck (8 Tools) | |

| 1 | Okuma LC40 15″ Chuck (12 Tools) 40 H.P. | |

| 1 | W&S WSC12 12″ Chuck (12 Tools) 25 H.P. | |

| Milling and EDM Machines | |

| Qty | Machine |

| 1 | Charmilles Electrical Discharge Machine (EDM) |

| 1 | Oerlikon M-08 Vertical, programmable, 3-axis |

| 1 | Oerlikon M-08 Horizontal, programmable, 3-axis |

| 1 | Bridgeport with “J” Head |

| 1 | Cincinnati Horizontal |

| 1 | Nichols Twin Mill |

| 1 | Nichols Rise and Fall |

| 1 | Cri-dan Thread Miller, 4″ capacity |

| Drilling Equipment | |

| Qty | Machine |

| 1 | Eldorado/Mega Gundrilling Machines, 1″ dia. x 10″ stroke |

| 1 | Burgmaster, 6-spindle, 1/4″ capacity |

| 1 | Steinel Multiple-Spindle, 5/16″ capacity |

| 1 | Kingsbury, 2-spindle, 3/8″ capacity |

| 1 | Leland-Gifford, 4- and 6-spindle, 3/8″ capacity |

| Grinders | |

| Qty | Machine |

| 1 | Bryant Internal |

| 1 | Jones & Shipman External and Internal Cylindrical |

| 1 | Harig 612 Surface |

| 1 | Overbeck Internal, to 5-1/2″ dia. |

| 1 | Cincinnati Centerless |

| 1 | Brown & Sharpe Surface |

| 1 | Elb-Schiff Surface, 20″ x 18″ table |

| 1 | Landis Cylindrical |

| 1 | Gardner Double Disc |

| 1 | Besly Double Disc |

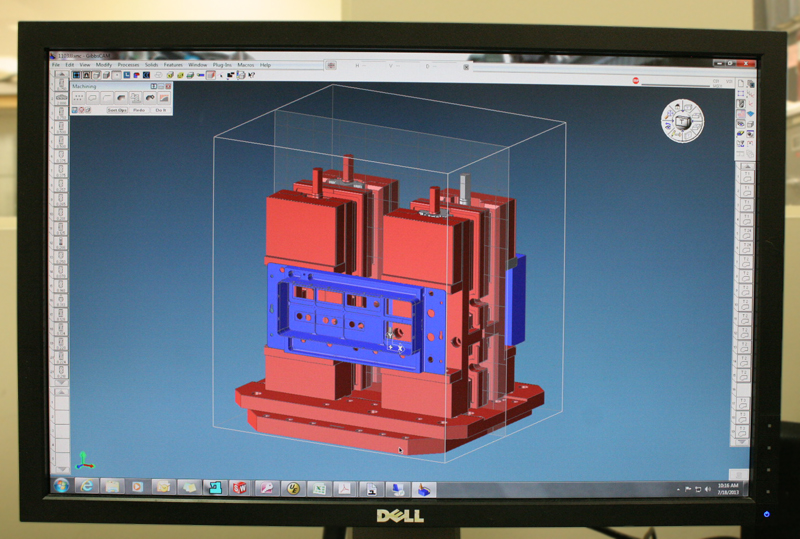

| CAD/CAM | |

| Qty | Machine |

| 1 | Automation Intelligence CAD/CAM system with NICAM IV, Expedite 3D and Anvil design and programming capability. System is IGES compatible. |

| Deburring and Polishing Equipment | |

| Qty | Machine |

| 1 | Almco ViBrader Tumbler, 10 cu. ft. |

| 1 | Almco ViBrader Tumbler, 20 cu. ft. |

| 1 | American Optical Microscopes, 7x-40x |

| Lapping and Honing | |

| Qty | Machine |

| 1 | Lapmaster 15″ |

| 1 | Lapmaster 24″ |

| 1 | Lapmaster 32″ |

| 1 | Lapmaster 48 “ |

| 1 | Sunnen Precision Home |

| Other Production Equipment | |

| Qty | Machine |

| 1 | Branson Degreaser |

| 1 | Branson Ultrasonic Degreaser |

| 1 | Gardner-Denver Air Compressor, 40 HP |

| 1 | Gardner-Denver Air Compressor, 50 HP |

| 1 | Walsh Punch Press, 18-ton |

| 1 | Electric Arc Induction Brazing Machine |

| 1 | Noblewest Rotary Marking Machine |

| 1 | Reed Vertical Thread and Roll Forming Machine |

| 1 | Marvel High Speed Band Saw with automatic bar feed |

Toolroom

| Jig Borers | |

| Qty | Machine |

| 1 | Moore No. 3 |

| Grinders | |

| Qty | Machine |

| 1 | Taft-Pierce Surface |

| 1 | Brown & Sharpe Cylindrical |

| 1 | Brown & Sharpe Surface |

| 1 | Cincinnati Tool and Cutter |

| 1 | Agathon Carbide Tool |

| 1 | Cincinnati Monoset Tool |

| 1 | Bench |

| 1 | K.O. Lee Cutter |

| Toolmakers’ Lathes | |

| Qty | Machine |

| 1 | Hardinge, 10″ swing |

| 1 | LeBlond, to 17″ swing |

| 1 | Mitsubishi High Speed |

| 1 | Schaublin, 6″ swing |

| 1 | Meuser, 20″ gap |

| Milling Machines | |

| Qty | Machine |

| 1 | Bridgeport with “J” Head, Series 1 |

| 1 | Bridgeport with “J” Head, Series 2 |

| 1 | Aciera Precision |

Quality Control

| Coordinate Measuring Machines | |

| Qty | Machine |

| 1 | Brown & Sharpe Validator 200-3618, 52″ x 72″ x 18″, with programmable computer and printer |

| 1 | Brown & Sharpe Validator 700-8100-2418, 36″ x 36″ x 18″, with HP-85 computer, .000050″ resolution |

| Electro-Mechanical Comparative Measuring Equipment | |

| Qty | Machine |

| 1 | ROI Model Omis II Video Probe System |

| 1 | Assortment of Air Gaging Equipment |

| 1 | Zygo Laser Bench Micrometer |

| 10 | Sunnen Bore Gages |

| 3 | Jones and Lamson Comparators to 100x |

| Digital Height and Bore Gages | |

| Microscopes | |

| Profilometers | |

| Statistical Process Control | |

| Qty | Machine |

| 1 | Swiss Precision Instruments SPI-Tronic Netproduct 1000 Stand-Alone Computer System with digital gaging |

| 4 | Netproducted SPC data collection stations with gauge interfaces |

| 1 | Compaq Desk Pro Computer System with auto interface to Brown & Shapre CMM, Phillip Crosby SPC II software package |

| Software Enhancements | |

| Qty | Machine |

| 1 | Visual Manufacturing |

| 1 | AutoCad Drafting System |

| 1 | Master Cam 3-Dimensional Programming System |